Revolutionizing Product Development with 3D Statistical Tolerance Analysis

In the fast-paced landscape of product development, advanced numerical simulation tools are game-changers. Among them, specialized tolerance analysis tools stand out, offering precise insights into variations in final products. By simulating potential deviation scenarios early in the design phase, these tools mitigate risks, reduce errors, and cut down on costly modifications during later project stages.

| Lucjan Strehar |

Digitalization in Action

Our journey into 3D statistical tolerance analysis began as a planned investment. In the context of our Digitalization project, we engaged with four providers, subjecting them to a "proof of concept" using a simple 3D assembly of our product. After rigorous evaluation, 3DCS Variation Analyst from Dimensional Control Systems emerged as the perfect fit. We acquired the license in October 2022, followed by training in the same month and a focused session in February 2023.

3DCS: A Closer Look

Functioning as a numerical simulation tool, 3DCS predicts variations in final products arising from tolerance ranges and assembly processes. The software enables us to minimize variations in production processes, ensuring the delivery of high-quality products in serial production. The simulation process begins with importing the 3D assembly into the 3DCS environment in nominal dimensions. Tolerance fields are assigned, and simulations are initiated, yielding sensitivity analyses, geo-factor analyses, and Monte Carlo simulations.

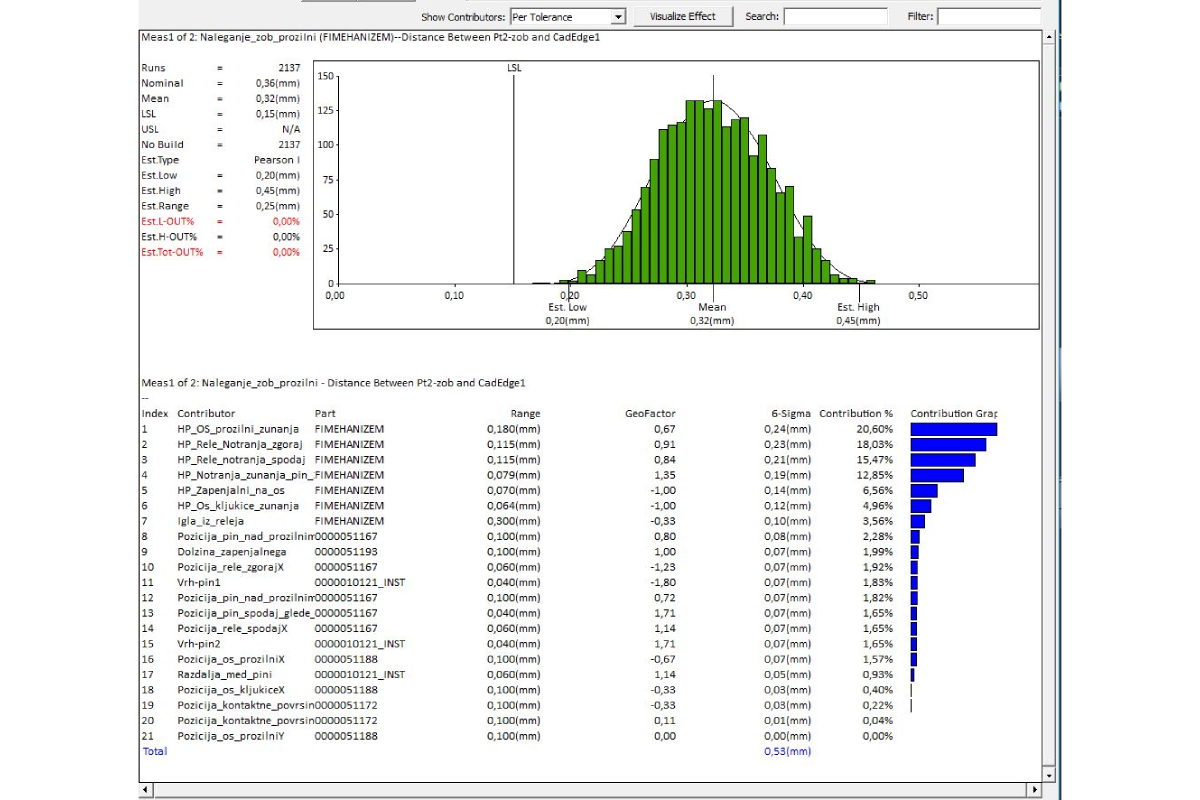

The result of the Monte Carlo analysis of the bearing surface of the two levers of the EFI-P mechanism and the contribution of individual tolerances

Unlocking Insights

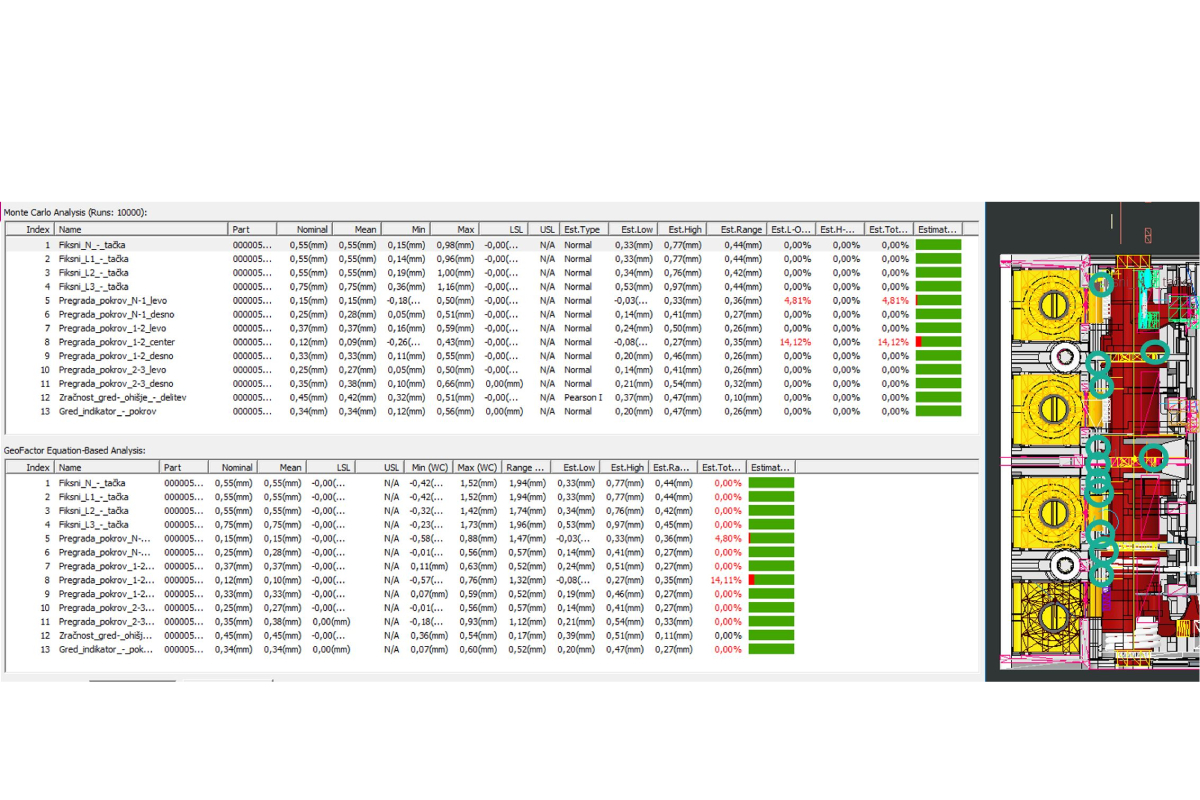

Monte Carlo simulations predict the percentage of good/bad final pieces based on thousands of virtual assemblies. Results empower us to take precise actions, adjusting component geometry or tolerance fields until positive outcomes are achieved. Results from Monte Carlo analyses provide critical insights into the statistical distribution of observed deviations, guiding us in optimizing designs, understanding impacts, and ensuring quality in serial production.

Calculation of the probability of collision between the shaft and the surrounding components in the EFI-P4 switch (before optimization)

Future-Ready Approach

Investing in 3D statistical tolerance analysis isn't just a move for today; it's an investment in future-ready product development. Modern tools have become indispensable for achieving the quality demanded by highly competitive markets, and we're committed to staying ahead of the curve.