Improving DC EV Charger Maintenance with IR-Based C IR Indication

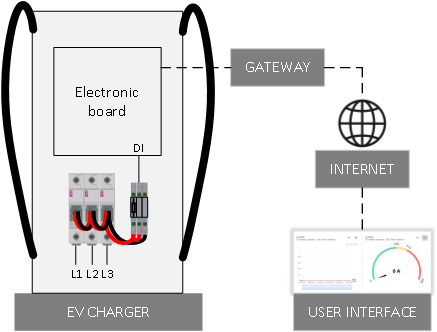

As electric vehicles (EVs) continue to gain popularity, the demand for fast and reliable charging infrastructure is surging. This has led to an increasing focus on ensuring that EV chargers, particularly DC fast chargers, operate efficiently and remain accessible to drivers during long journeys. One of the critical challenges in maintaining these charging stations is minimizing downtime caused by electrical failures, which can disrupt service and delay repairs. In this case study, we explore how ETI’s innovative C IR indication module provides a cutting-edge solution for monitoring and maintaining the electrical wiring within DC EV chargers, improving both reliability and maintenance efficiency.

1. Fast DC Chargers

Electric vehicles (EVs) are becoming more common, and with them, there is an increasing demand for reliable and accessible charging infrastructure.

The main purpose of DC EV chargers is to quickly refill the EV battery during long journeys. Consequently, EV chargers are usually positioned along highways at existing petrol stations. The distance between EV charging stations can be considerable, and any failure in the electrical wiring results in an unexpected and unwanted shutdown of the charging station. Because of the long distances between stations, maintenance is more difficult, as it takes time for the maintenance team to reach the failed device. Any information regarding the potential failure is highly valued.